Semiconductor Shortage Highlights Need to Strengthen U.S. Chip Manufacturing, Research

Thursday, Feb 04, 2021, 3:30pm

by Semiconductor Industry Association

Semiconductors are the brains of modern electronics, enabling highly advanced technologies in healthcare, communications, computing, and transportation, among many other applications. Global semiconductor sales increased 6.5 percent in 2020, demonstrating growing demand for chips across a range of end markets.

In the automotive space, chips have made our cars exponentially smarter, safer, and more efficient, but a global shortage of certain semiconductors has impacted the automotive market, slowing production of some cars. The shortage is largely the result of substantial swings in demand due to the pandemic and the increased use of semiconductors in advanced vehicles. The semiconductor industry is working diligently to ramp up production to meet renewed demand.

[Learn more: “Chipmakers Are Ramping Up Production to Address Semiconductor Shortage. Here’s Why that Takes Time“]

Rising overall demand for semiconductors and their ever-increasing importance throughout the economy has captured the attention of policymakers in Washington. Congress enacted legislation earlier this year calling for federal incentives for domestic chip manufacturing and investments in semiconductor research to meet this growing demand. Policymakers now must appropriate funding for these provisions to reinforce American leadership in semiconductors, strengthen the U.S. economy and job creation, and make semiconductor supply chains more resilient to future crises.

The events leading to the current auto chip shortage began during the second quarter of 2020, when automakers understandably reduced production and chip purchases as the virus spread across the globe. Chipmakers, meanwhile, saw surging demand for semiconductors used to enable remote healthcare, work-at-home, and virtual learning, which were needed during the pandemic.

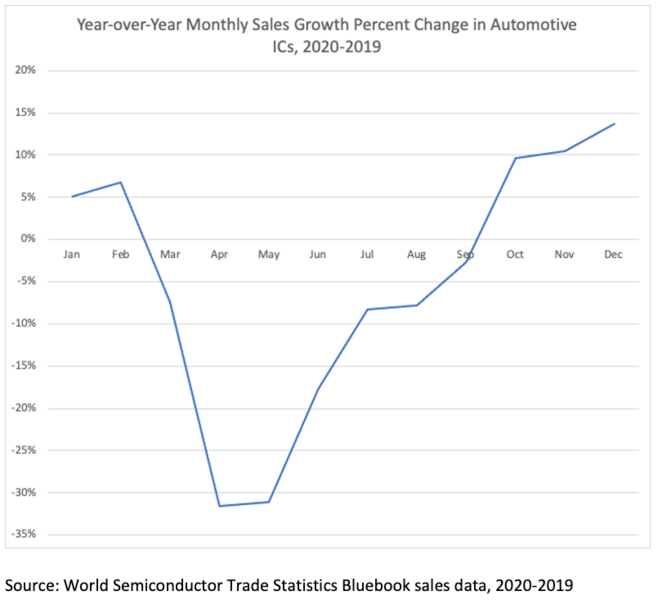

In the months that followed, demand for automotive semiconductors rallied much more quickly than most anticipated. The chart below illustrates this development. The clear decrease in monthly year-over-year (YoY) sales growth for application-specific chips used in the automotive market was sudden and precipitous in March and April, when the pandemic was shuttering auto plants globally. Equally as pronounced was the rapid recovery in YoY sales during Q3 and Q4. In fact, monthly YoY Q4 sales had recovered to be positive again. This chart clearly illustrates a V-shaped downturn and recovery in auto chip sales.

As mentioned, the semiconductor industry has worked to ramp up production to meet the steep jump in demand, but this supply-demand imbalance cannot be remedied with the “flip of a switch.” Restoring market balance takes time. Semiconductor manufacturing is not suited to rapid and large shifts in demand, since it takes time to ramp up semiconductor production. Making a semiconductor is one of the most complex manufacturing processes. Lead times of up to 26 weeks are the norm in the industry to produce a finished chip. Most industry analysts believe the current short-term supply shortage will ease in the coming months as supply adjusts to meet demand.

The shortage is a reminder of the essential role semiconductors play in so many critical areas of society, including transportation. This trend will only continue as demand for electronics and connectivity grows. In the auto space, new vehicles increasingly rely on chips for fuel efficiency, safety, and other features. The expected growth in electric cars will only further this reliance. In the long-term, as chips play an even bigger role in an ever-expanding array of products, global demand for chips will continue to rise.

A core priority of the semiconductor industry is therefore to promote federal incentives for chip manufacturing in the U.S., so our country is positioned to produce the chips needed to meet rising long-term demand. As noted above, SIA strongly supports the provisions enacted in the National Defense Authorization Act authorizing federal incentives for domestic semiconductor manufacturing and investments in semiconductor research, as well as efforts to bolster manufacturing through an investment tax credit. But it is not enough to authorize these provisions. We must ensure they are fully funded. That means the Biden administration and Congress need to work together and provide substantial funding to bolster U.S. chip manufacturing and research.

We look forward to working with the new administration and Congress to fully fund these provisions and usher in a historic resurgence of semiconductor production in the U.S.